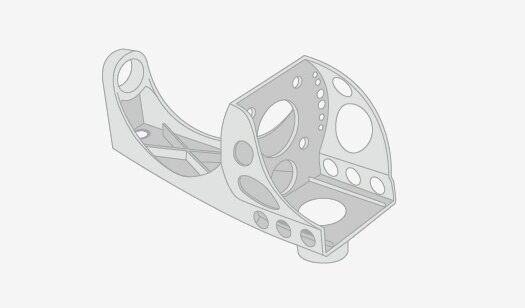

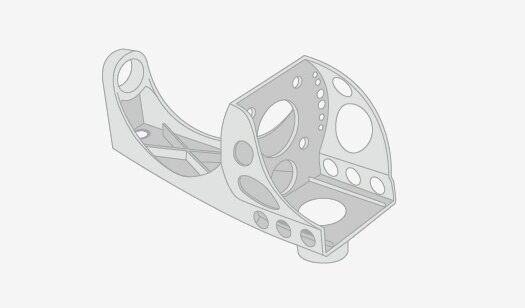

High-Resolution SLA Prototypes

SLA technology is used for its extremely accurate and high resolution parts. These parts are capable of being used as end-use, low-volume production or even for rapid prototyping. TechnoPrints offers a variety of materials, feel free to contact us.

Our SLA 3D Printers

Prusa SL1S SPEED

Print Volume: 127 x 80 x 150 mm. (5 x 3.14 x 5.9 inches)

Materials: Standard resin, Clear resin, casting resin, Hard and resistant resins, heat resistant resin, bio-compatible resins and flexible resins

LCD Resolution: 5.96″ 2560 x 1620p

Layer Resolution: 0.025 – 0.1mm

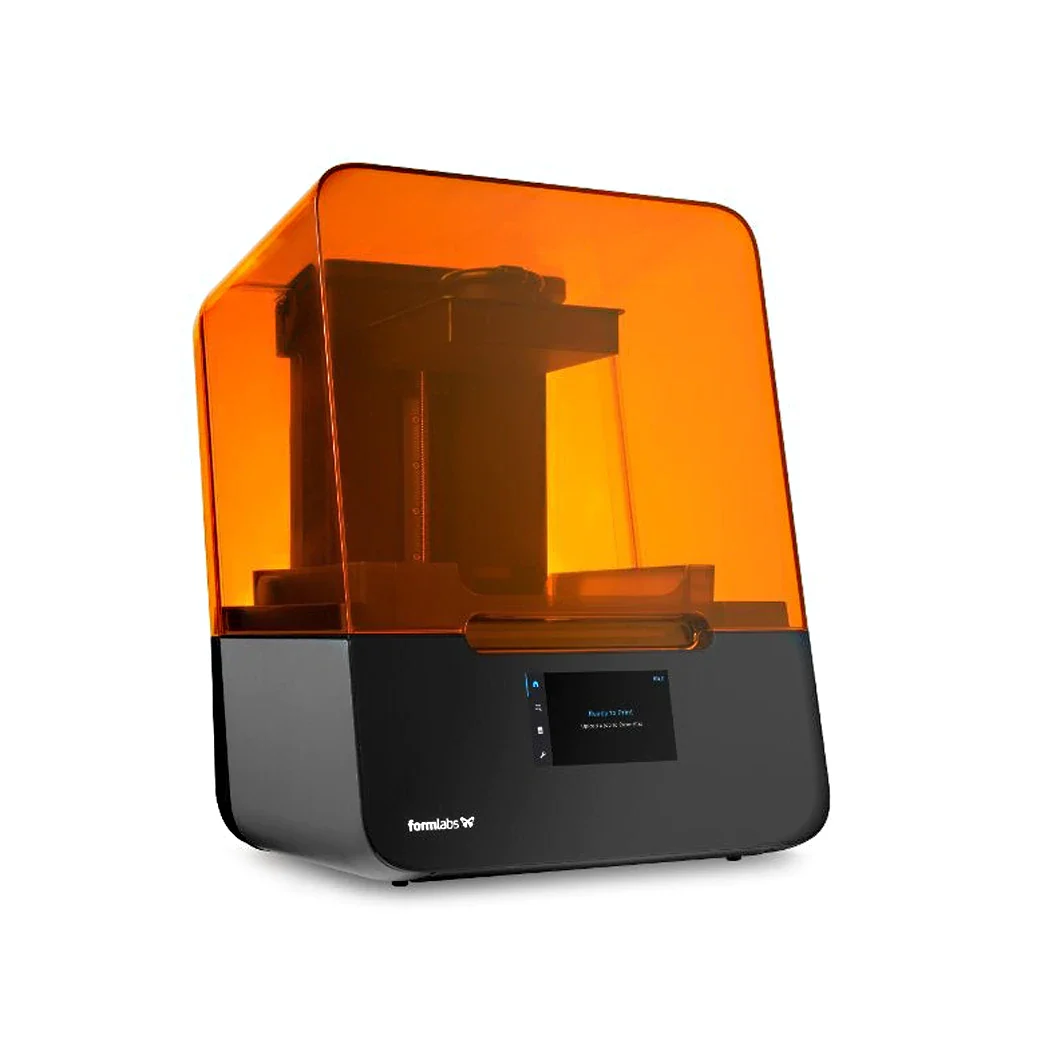

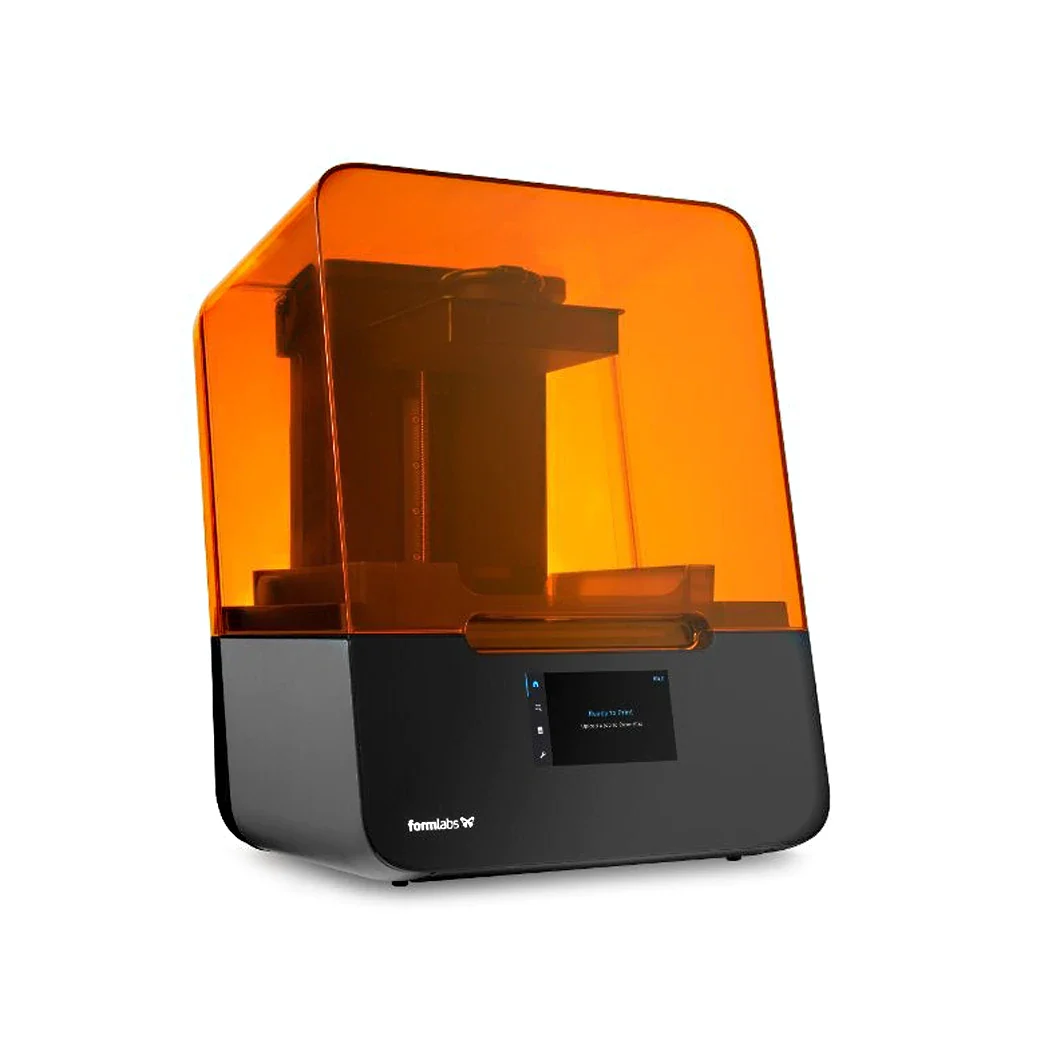

*Coming Soon* FormLabs 3

Print Volume: 145 x 145 x 185mm. (5.7 x 5.7 x 7.3 inches)

Materials: Varity of resins available

Dimensional Accuracy (X/Y): 25 / 25 microns

Layer Height: 0.025 – 0.30mm

Applications of SLA Printing

SLA printing can be used in a variety of industries. Here are some examples of what can be accomplished.

Dental

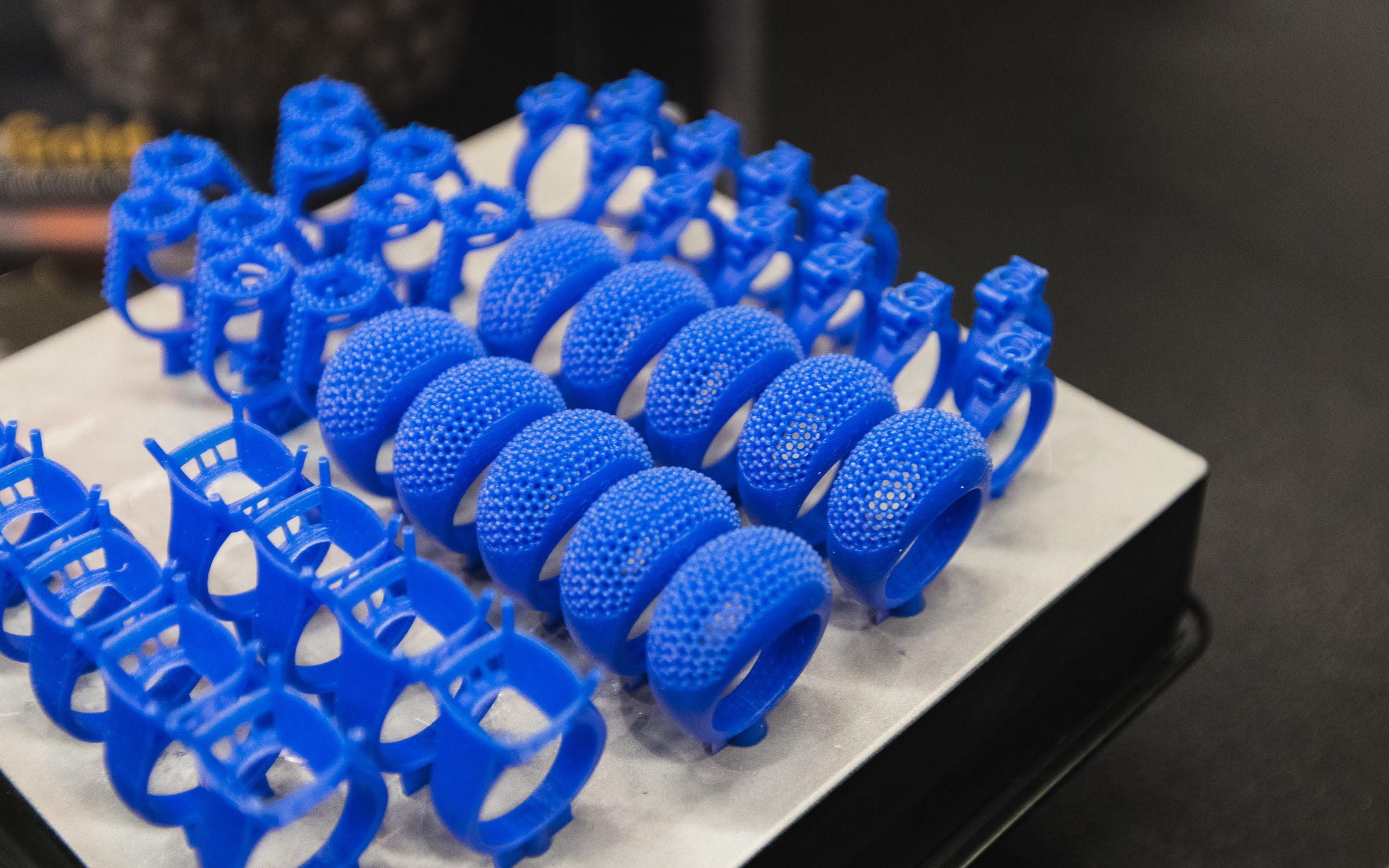

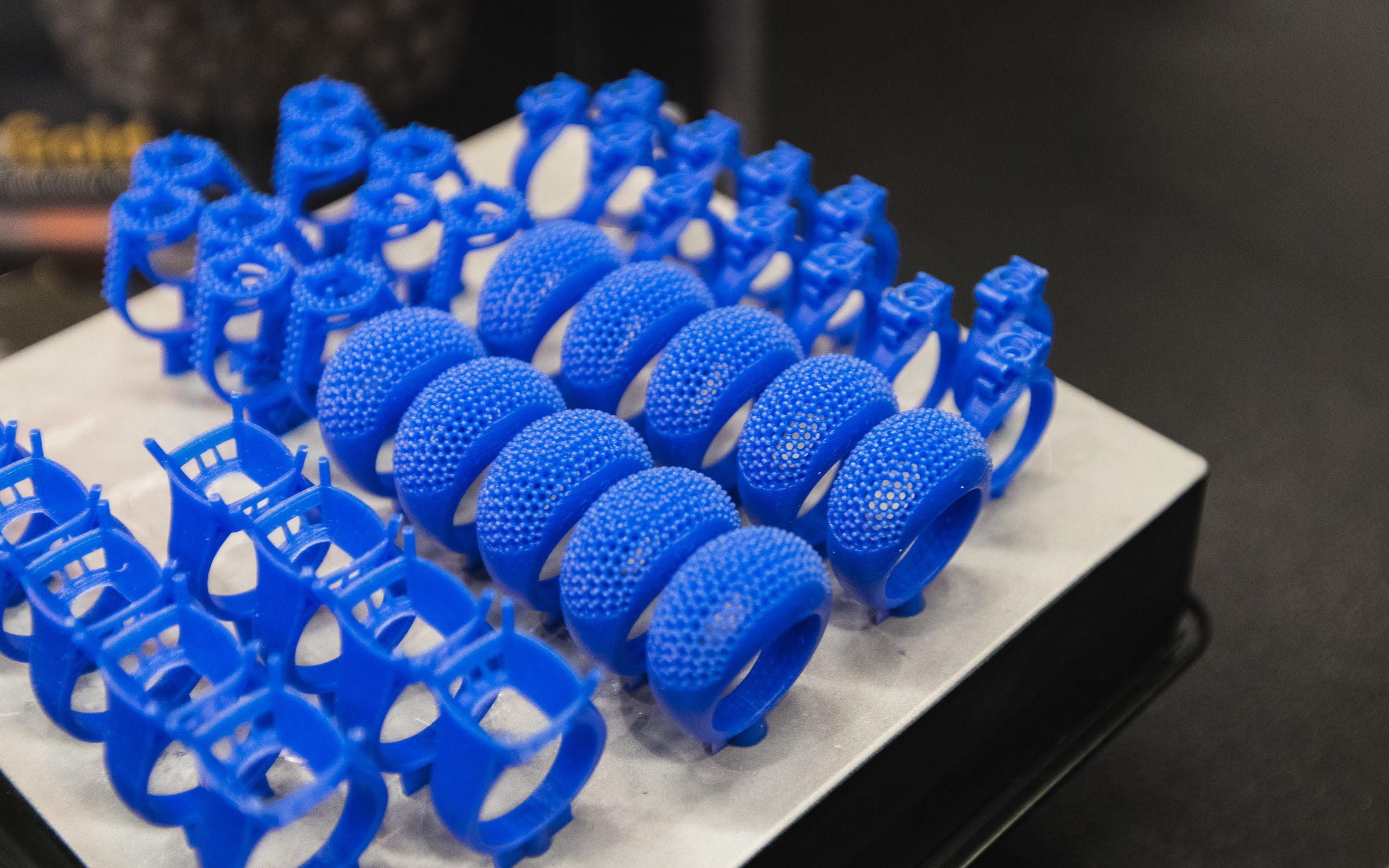

Jewellery

Miniatures

Jigs and Fixtures

Dental

Medical

SLA Materials

Selecting the best material for your project is very important to us. From Tough Resin to flexible rein, we offer a wide variety of materials and are happy to assist you in choosing the resin that best suits your project needs.

Standard Resin

Smooth surface, lots of details

Fragile

Not suitable for mechanical parts

Tough Resin

Similar to ABS materials

Partially flexible

Suitable for mechanical parts

Low resistance to high temperatures

Flexible Resin

Similar to rubber (70A hardness)

Lower resolution of printed parts

Heat Resistant Resin

Highly temperature-resistant

Used for injection forms

Expensive

Bio-compatible resins

Non-toxic

Suitable for dental implants manufacturing

Abrasion-resistant

Expensive

Casting Resin

Lots of details

Great for preparation of casting forms

Little to no remnants after burning the resin

Quality Comparison

Not sure which 3D Printing quality to choose from? By choosing standard quality can significantly reduce costs at a cost of more visible layers. However, choosing a Ultra quality will result with a higher quality finish and an increase in price.

FDM Layering heights are pictured below

Standard Quality

Mid Quality