Recent Completed Projects

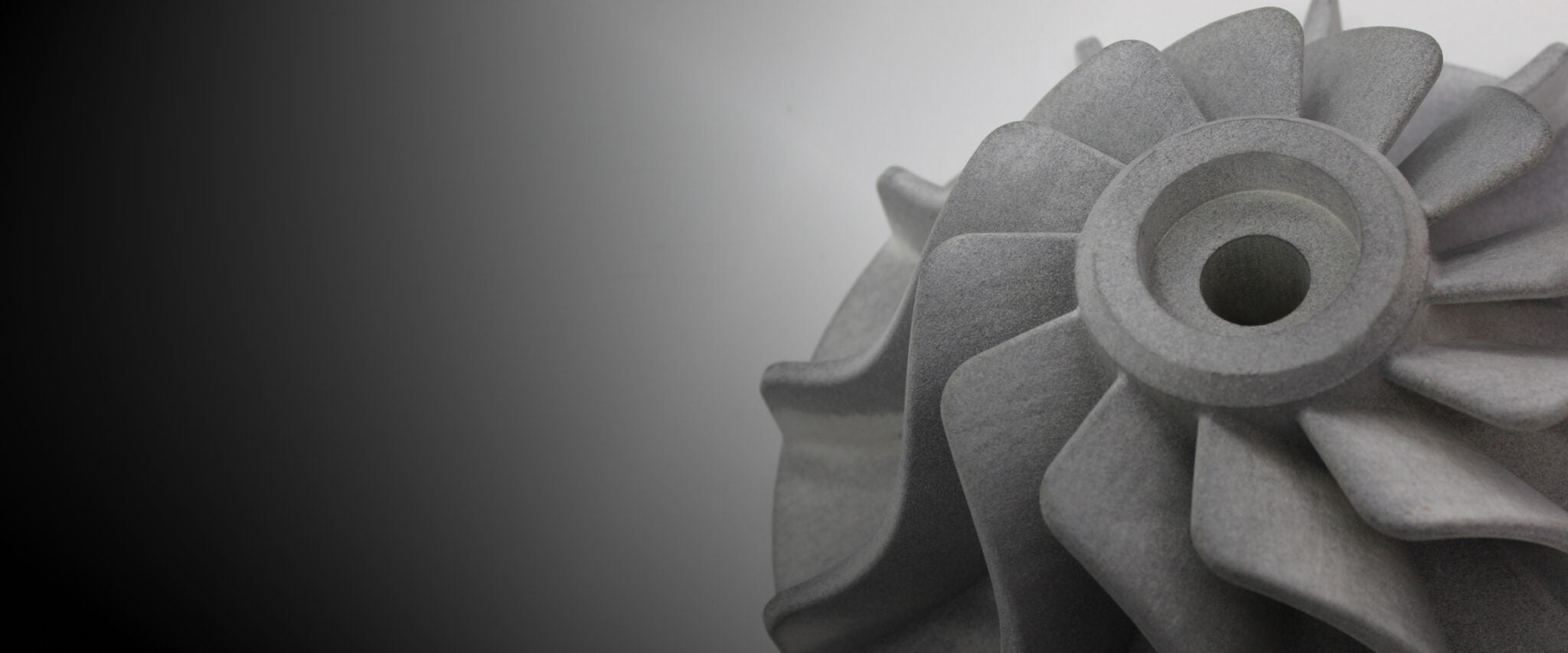

Rapid Physical Prototypes

Move from digital design to a tangible product in days, not weeks. We create high-fidelity, functional prototypes using FDM, SLS, and SLA technologies, allowing you to test fit, form, and function immediately. Validate your design, catch flaws early, and accelerate your product development cycle with precision physical models.

4-Step Rapid Prototyping Service Process

Design & File Preparation

The process starts with Design & File Preparation. Customers must contact us at contact@technoprints.ca to submit their existing 3D files (STL, OBJ, etc.) or to request assistance in creating a digital 3D model from a drawing or broken part.

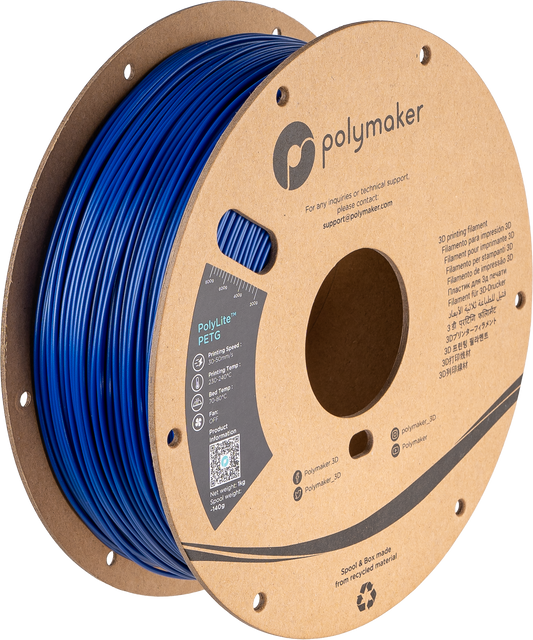

Material & Technology Selection

We evaluate the part's intended application use and environmental factors, including where the forces are applied, if it is for outdoor or indoor use, and any expected water exposure or heat levels. This thorough assessment ensures we select the appropriate material (e.g., Nylon, Resin) and technology (e.g., FDM, SLS) that perfectly meets the prototype's functional requirements.

Quotation & Order Confirmation

We then issue a detailed Quotation & Order Confirmation based on material, technology, time, and specific quantity. Order approval requires payment, which can be made via e-transfer to our email, credit card, Purchase Orders (PO's), or cash.

Production & Fulfillment

The final step is Production & Fulfillment. We print, post-process, and quality-check the parts, then arrange for final delivery by offering customers the option to ship out or organize local pickup of the finished rapid prototypes.

Laser Engraving Services

We offer professional laser engraving services for a wide range of materials. From personalized gifts to custom business products, our precision laser technology delivers exceptional results every time.

Silicone 40A Material

Experience the flexibility and durability of Silicone 40A material for your custom 3D printing projects.

Applications

- Customized prosthetics, orthotics, audiology models, and medical devices.

- Seals, gaskets, grommets, connectors, and dampeners for automotive, robotics, and manufacturing.

- Wearables, handles, and grippers for consumer products.

- Flexible fixtures, masking tools, and soft molds for casting urethane or resin.